NVELOPE

- Overview

- Availability

- Gallery

- Downloads

- Support

Overview

Overview Coming Soon

ULTRACORE IQ intelligent core panel is Deemed-to-Satisfy non-combustible when tested to AS 1530.1 and AS 1530.3 as per the requirements of the NCC 2022, Clause C2D10(6)(g) and installed using the mechanical cassette-fix system as per NCC 2022, Clause C2D15(1). It has also been tested by Exova Warringtonfire to BS 8414 and AS 5113 full-scale testing to prove it does not contribute to the spread of fire. Visually, ULTRACORE IQ intelligent non-combustible core panel looks the same as traditional aluminium composite panel but with zero combustible core content (0%) meaning it achieves the lowest risk rating, category D, from the Insurance Council of Australia.

Proven V-groove Durability

Unlike 3mm SOLID aluminium, ULTRACORE IQ has 40 years of proven durability when using the common v-groove folding system. This is because the front skin is not impacted when v-grooving, as has always been intended.

AS 1530.1 Non-combustible

ULTRACORE IQ is one of the few aluminium panels globally that is Deemed-to-Satisfy non-combustible when tested to AS 1530.1 and AS 1530.3 in accordance with the NCC 2022 Clause C2D10(6)(g) requirements.

AS 5113 Fire Testing

ULTRACORE IQ is Deemed-to-Satisfy non-combustible so does not require further fire testing however it has been tested to AS 5113 full-scale testing by Exova Warrintonfire to prove it does not contribute to the spread of fire.

Zero Polyethylene Core (0%)

Unlike most other aluminium panel products including FR, Plus, A2 and NC type panels, the ULTRACORE IQ aluminium core contains ZERO percent flammable polyethylene (0%) and each lamina is 100% non-combustible.

Less Thermal Conductivity

ULTRACORE IQ aluminium core panel has a thermal conductivity of 2.54 W/mK compared to 205 W/mk for a SOLID aluminium panel. This means 80 x slower rate of heat transfer for greater fire safety and section J compliance.

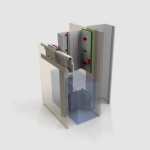

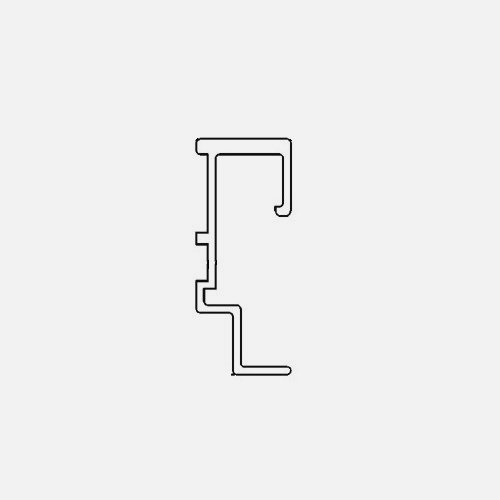

Mechanical Cassette-Fixing

Compared to a SOLID aluminium panel, ULTRACORE IQ is faster and easier to fabricate using the well-proven z-angle cassette-fix system making it more cost effective and compliant with C2D15(1).

Oil-canning Resistance

Oil-canning is the uneven distribution of tension in SOLID aluminium panels which results in a rippling effect on the facade. The superior mechanical properties of ULTRACORE IQ guarantees against oil-canning.

Less Carbon, Less Weight

ULTRACORE IQ intelligent core panel is 100% recyclable and uses 50% less aluminium per m2 than 3mm SOLID aluminium for much less carbon footprint. It is also 50% lighter for significant structural and labour savings.

Availability

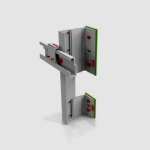

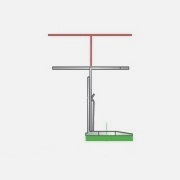

Nvelope Aluminium Framing System

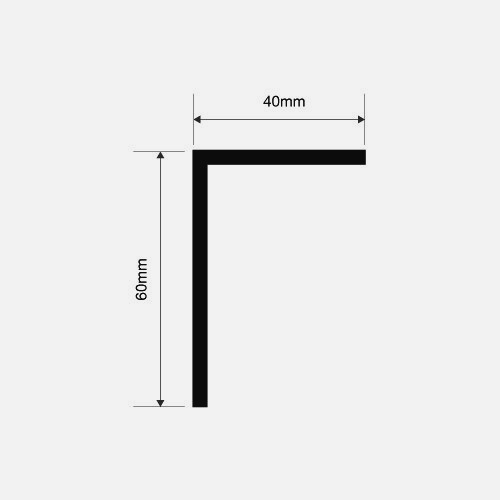

| NVL6060 60mm L-Rail |

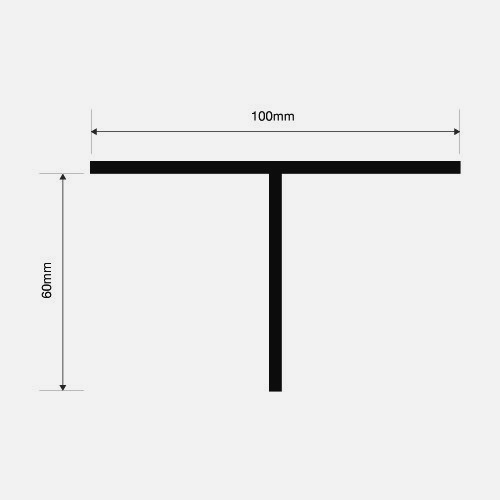

NVT**60 40/60mm T-Rail |

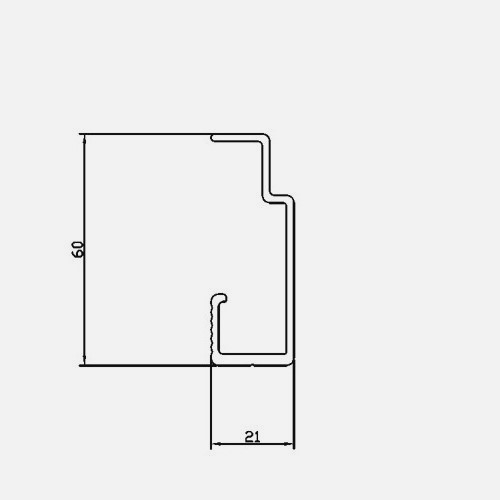

NV3CR60 NV3 Carrier Rail |

NV3TS*H NV3 Hanger |

NVBS/BD40 40mm Bracket |

NVBS/BD60 60mm Bracket |

|

|

|

|

|

|

| Code |

Description |

Lead Time |

MOQ |

|---|---|---|---|

| NVT4060 | NVELOPE 40mm Vertical T-Rail, 6.0m Length | 1-2 Weeks | 1 Length |

| NVT6060 | NVELOPE 60mm Vertical T-Rail, 6.0m Length | 1-2 Weeks | 1 Length |

| NVL6060 | NVELOPE 60mm Vertical L-Rail, 6.0m Length | 1-2 Weeks | 1 Length |

| NV3CR60 | NVELOPE NV3 Carrier Rail, 6.0m Length | 1-2 Weeks | 1 Length |

| NV3TSLH | NVELOPE NV3 TUF-S Leveling Hanger (Use with TS6CA**) | 1-2 Weeks | 1 Unit |

| NV3TSSH | NVELOPE NV3 TUF-S Static Hanger (Use with TS6CA**) | 1-2 Weeks | 1 Unit |

| NVBS40 | NVELOPE 40mm Single Bracket (6.5/11mm holes) | 1-2 Weeks | 1 Unit |

| NVBD40 | NVELOPE 40mm Double Bracket (11mm hole) | 1-2 Weeks | 1 Unit |

| NVBS60 | NVELOPE 60mm Single Bracket (6.5/11mm holes) | 1-2 Weeks | 1 Unit |

| NVBD60 | NVELOPE 60mm Double Bracket (11mm hole) | 1-2 Weeks | 1 Unit |

| NVS2055 | NVELOPE 20mm x 5.5g Universal Fixing Screw, 500 Pack | 1-2 Weeks | 1 Pack |

| FIXINGS | EUROFIX Tuf-S Concealed Anchors to Suit NV3 - CLICK HERE | 1-2 Weeks | 1 Pack |

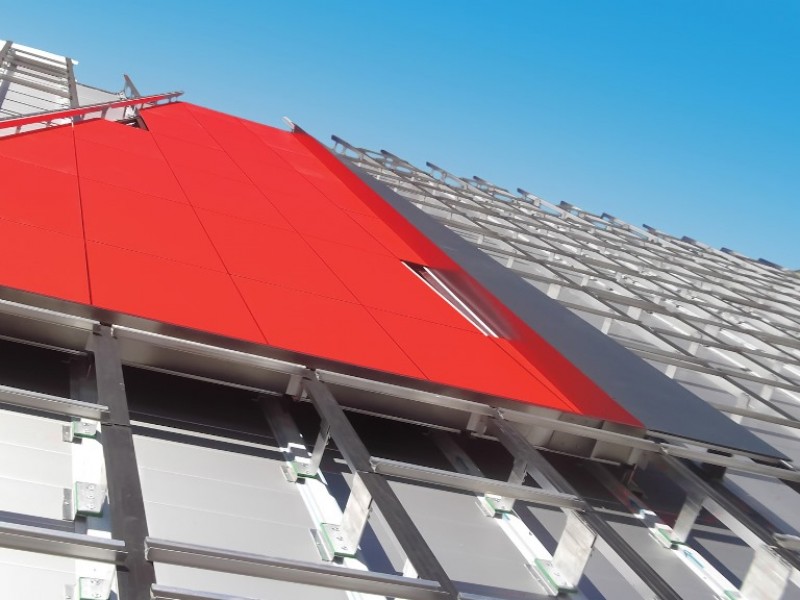

Gallery

Downloads

Support

Customer Support

For same day design assistance and technical support please contact our sales team directly on the below contact details. All our sales and technical staff are locally based so we can provide the best possible service and support for your project. You can also request a technical data sheet or project quotation using the below email links;

| Frank Kutra |

| Product Manager |

| 1300 945 123 |

| 0477 966 027 |

| LinkedIn Profile |

- Overview

- Availability

- Gallery

- Downloads

- Support